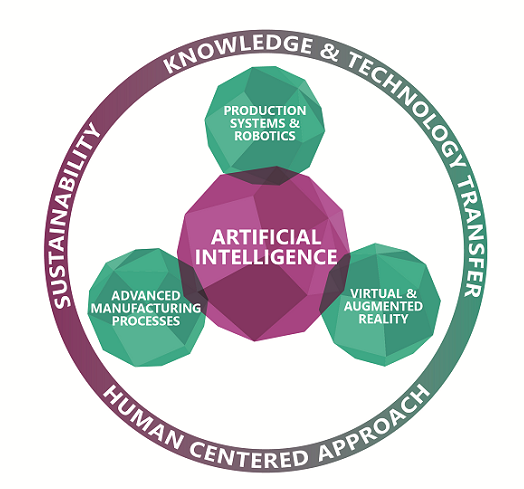

Advanced Manufacturing Processes

Advanced and sustainable manufacturing processes adapted to new and lightweight materials are a key issue for the Industry of the Future. The joint activities deal with processes like additive manufacturing, forming, machining, and heat treatment and look for efficiency, robustness, and performance in process chains for complex parts. The focal interest of the institute is the optimization of the mechanical, metallurgical, and topological states of the surface and near-surface layers (also referred to as surface engineering) for an improved functional performance and life of components.

Production Systems & Robotics

Production systems will undergo a significant change in the future. The industry of the future will be shaped significantly by the opportunities associated with digitization of products, processes, and resources. Future production systems will be characterized by high complexity, agility, and they will be highly performing, environmentally friendly, and socially sustainable. This working group mainly focuses on agile value networks, excellence in manufacturing, and the human factor. We combine theoretical and lab work and feedback from case studies in industry, in France, Germany, and globally.

Flexible robot-based production concepts will be a key factor for the competitiveness of the European manufacturing industry. The ”Robotics” research axis focuses on the development and promotion of new robot technologies for industrial applications, including a stronger inter-connectivity between components, heavy data-driven approaches to the development of (semi-) autonomous robot systems as well as flexible and intuitive human-robot interaction concepts. Key element in these new production scenarios will be the safety of the human operator in the close proximity of the robot.

Virtual & Augmented Reality

Fast and targeted innovation processes are at the core of Industry of the Future to produce high-end products. Virtual and augmented reality is a key element for modern working environments. Our joint activities support the “view of the whole at any moment” by connecting product lifecycle management with human-centered design and validation. Our unique facilities in Europe (CAVE systems, head-mounted displays, and many more) enable the development of digital twins, virtual-factory, interaction in virtual reality environments and presence and immersion in driving simulation.